Blister Packing is typically used by pharmaceutical companies to package tablets and capsules. Given the need for accuracy and flawlessness with regard to the products as well as the packaging in the pharmaceutical industry, these blister packs need to be checked thoroughly.

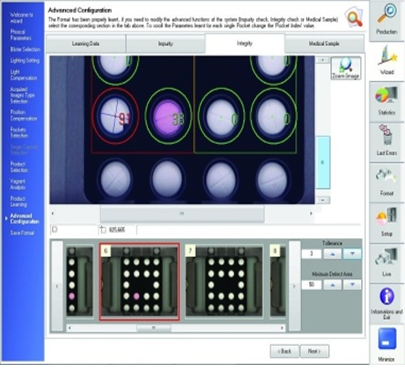

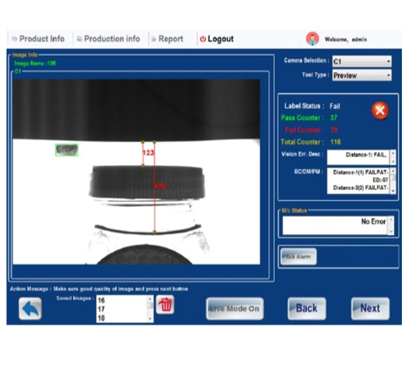

A camera based inspection system like Bliss, installed on the packaging line, is the most efficient way to inspect and verify all the elements of a blister pack.

Bliss can be used to inspect all the types of blister packs commonly used by pharmaceutical companies. Additionally, it performs reliable inspection of any kind of aesthetic fault in the tablet or capsule.

This automatic system can also be used for inspecting PVC clear, opaque, color, aluminum foil, a clear film etc.

Bliss vision inspecton systems can detect:

Missing Tablets

Wrongly Shaped Tablets

Cracked/Broken Tablets

Color Differences (Bi-color, Tricolor Tablet/Capsule)

Object Oversized and Object undersized Area

Misalignment of Tablet

Presence 'absence of 2D Barcode ard Pharma Code

Barcode System Our company can supply the production lines on your factory by the best of Barcode systems.

Labeling Machines

Our company introduces manufacture intelligent labeling equipment, such as:

Integrated smart labeling system

On-line printing and labeling system

on-line variable code printing system

Production management and product quality traceability system

RFID Application...

Automatic packaging solution.

All labeling machine have passed IS09001 and CE certificate.

Level liquid check Label presence Logo presence Barcode ID and 2D

OCV / OCR text inspection Laser marking inspection.

We can supply your company by any type of printer which will be suitable for any packaging material

Viols & Ampoules Inspection Machine

We can supply your company by any type of Inspection Machine which will be suitable for your needs

Most of its structure is made from stainless steel and is supported by latest automation technology' Large color touch screen for excellent visibility and easy operation of the system is not only reducing operator errors but also make packing line more efficient & accurate.

It is a technology to check completeness & correctness of any finished / semi finished products through image processing. It can be applied for automated online inspection process or offline inspection process.